FAQ

Technology Questions?

The manufacturing process of para-aramid mainly includes two processes: polymerization and spinning.

do we offer?

Para aramid filament yarn

Aramid filament yarn comes in a variety of mechanical properties,

categorized simply as:

• Standard modulus with high elongation

• High modulus

• High tenacity

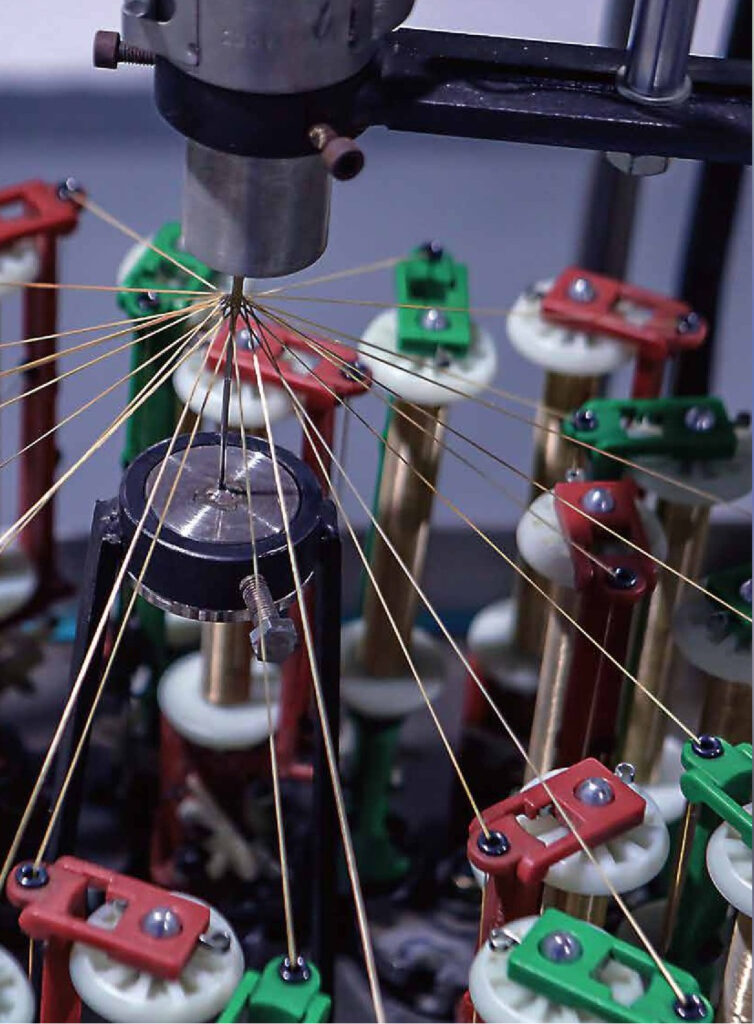

Aramid resin is dissolved in concentrated sulfuric acid solution to prepare spinning slurry, Aramid fiber can be obtained after the process of measuring, spraying, washing, drying and shaping, oiling and winding by spinning machine. In the production process, the para-aramid fiber forming process is demanding, the highly orientation process only occurs in the air layer of 5~10mm, the formation of its structure is completed in only 0.04 seconds, and the diameter of each filament is as low as 12µm, It is the unique spinning process in chemical fiber forming so far.

Aramid fiber, or known by many as Kevlar (DuPont’s brand name), belongs in a family of synthetic products characterized by strength (some five times stronger than steel on an equal weight basis) and heat-resistance (some more than 500 degrees Celcius). It is appropriate for various applications such as composites, ballistics, aerospace, automotive, protective clothing against heat/radiation/chemicals, asbestos substitute, telecommunications (optical fiber cables) and many other.

The word aramid comes from a blend of the words “aromatic” and “polyamide” and is a general term for a manufactured fiber in which the fiber forming substance is a long chain synthetic polyamide, in which at least 85% is of amide linkages (-CO-NH-) attached directly to two aromatic rings, (as defined by the U.S Federal Trade Commission.)

Woven fabric is a woven fabric made of filament as raw material, plain weave, twill weave and satin, which has the characteristics of cutting and puncture-proof.

UD cloth is a kind of unidirectional non-weft cloth, which is orthogonally composite of aramid fibers or polyethylene fibers arranged at 0° and 90°, coated with resin and hot-pressed molding, which is currently the most advanced form of human protective fabric in the world. The fibers in each layer of UD cloth are arranged in parallel, and the strength loss of the fibers during processing is minimal.

Staramid International has seized the opportunities on the global Aramid fiber market by building a complete production and supply chain. With facilities in the city of Yizheng as our production powerhouse, we aim to surpass the competition in scale and output, becoming the second-to-none supplier of Aramid fiber worldwide. Staramid is a reliable aramid fiber exporter and offers solutions, for composites and ballistic protection, with worldwide shipping capability.

Request a Quote Today

Reach Us

Location:

36-B W 1st Ave, Miller, SD 57362, Mexico

Email:

Phone:

+86-186-7080-4253

+1 123-456-7890